NEWS

New Horizon College, Kasturi Nagar, had arranged one day industrial visit to Karnataka Silk Industries Corporation Limited (KSIC) Karnataka for VI Semester B.com students (SECTION A) On 06th February 2020

INDUSTRIAL VISIT REPORT

New Horizon College, Kasturi Nagar, had arranged one day industrial visit to Karnataka Silk Industries Corporation Limited (KSIC) Karnataka for VI Semester B.com students (SECTION A) On 06 th February 2020 the students were accompanied by two faculties Ms. Prathima and Ms. Kalpana. The travel journey started in the early morning by 6.30am with 51 students.

OVERVIEW

Karnataka produces 9,000 metric tons of mulberry silk of a total of 20,000 metric tons of mulberry silk produced in the country, thus contributing to nearly 45% of the country’s total mulberry silk. In Karnataka, silk is mainly produced in the Mysore district. It is a patent registered product under KSIC. KSIC is an owner of the Mysore Silk brand.The growth of the silk industry in the Kingdom of Mysore was first initiated during the reign of Tipu Sultan nearly 1780- 1790AC. Later it was hit by a global depression, and competition from imported silk and rayon. In the second half of the 20th century, it revived and the Mysore State became the top multi-voltine silk producer in India

COMPANY PROFILE

From the land of silk and sandalwood comes a fine textile fit for royalty. The Mysore silk saree is manufactured in Karnataka, which happens to be one of the largest mulberry silk producers in the country.

VISION and MISSION

“To provide employment directly and indirectly producing goods, products and marketing effectively in the market.” “Manufacturing and marketing of Mysore silk sarees”

ORIGIN AND HISTORY

The growth of Mysore silk saree is credited to the region of Tippu sultan in 1785 AD.but what has kept the craze of going is the quality of fabric, a mix of fine silk and pure gold zari that comes together to create a perfectly stylish piece of south Indian culture for the discerning global fashionista

WEAVING PROCESS

It was the maharaj of Mysore who established the first silk factory in the year 1912- the Mysore silk weaving factory is now owned by Karnataka silk industries corporation (KSIC), a government enterprise, and exclusively manufactures Mysore silk.

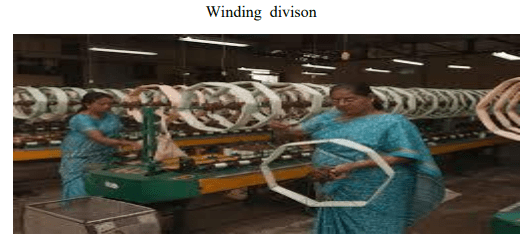

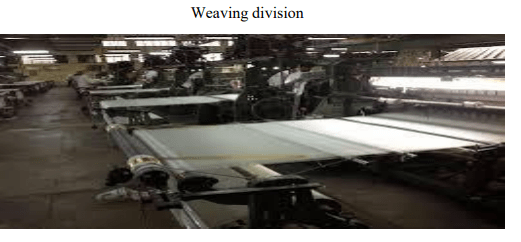

The raw materials used in making the saree obtained from a single cocoon, which then goes to the silk weaving factory where the destiny of the silk fiber is measured and prepared. This is followed by various steps like soaking, twisting, wefting, and winding. Once the winding is done, the yarn is ready to be weaved. The weaving process involves two types of looms- the dobby loom and jacquard loom.it takes about 6 hours to make one sareeafter which the next step-degumming begins. Degumming helps to smoothen the fabric. The saree is then sent to dye and wash The semi dry saree are steam ironed on a massive machine, and the saree is then cut into desired length. Each saree measures about 5.5 meters and the pallu is made with an exquisite design and has a blouse piece material attached to it

COLOURS

The saree have a standard, single colour with gold borders and zari on them. While the traditional hues of orange, red and green are famous

PRICE RANGE

Any original Mysore silk saree can cost you anywhere between Rs. 15,000- 30,000. The more expensive ones can go up to Rs.500, 000

PRESENT STATUS

KSIC produces 6,000 sarees every year and armed with GIR certificate, KSIC now plans to have a distributor in every state.

Observation of the students Students

observed the process of thread making, colors used for making thread and the weaving process of the sarees. The employees were happy and patient enough to address the various questions put forward by the student’s .We appreciate staff member who guided students with each and every question in detail. We would like to extend our gratitude to the KSIC for permitting and supporting us, to make our visit a success with accomplishment of objectives